Anjing Road, Xiaolan, Zhongshan, Guangdong, China

info@mes-drive.com

08.00 AM-09.00 PM

Yesterday’s headline—embedding a robot arm that can lift a crate, slot it into a shelving bay, and return for the next task in under six seconds—ignited a surge of conversation across tech blogs and logistics forums. That fleeting clip, featuring Amazon’s latest Panda‑Swan autonomous worker, was a reminder that the globe‑wide shift towards robotic warehousing isn’t just a futuristic dream; it’s already reshaping every screw, conveyor belt, and elevator shaft in high‑traffic distribution centers. While the media basks in the image of a sleek robot swarming aisles, the silent, working hero behind these sweeping efficiencies is the humble gear motor, more specifically the gear motor reducer. In this article we trace the path of that motor from the bustling Amazon warehouses it powers to its broader implications for the future of automation.

In October, Amazon unveiled its fourth generation of pod‑based workforce—Panda Swan. The company claims the new robots can handle twenty‑three standard package heights while performing 95 % of conventional picker tasks. According to internal estimates, each robot can increase throughput by up to 35 % while cutting human labor costs by almost half. The surge in automation has drawn commendation from venture capital, supply‑chain analysts, and even policymakers who view it as a prototype for the future of labor‑intensive industries.

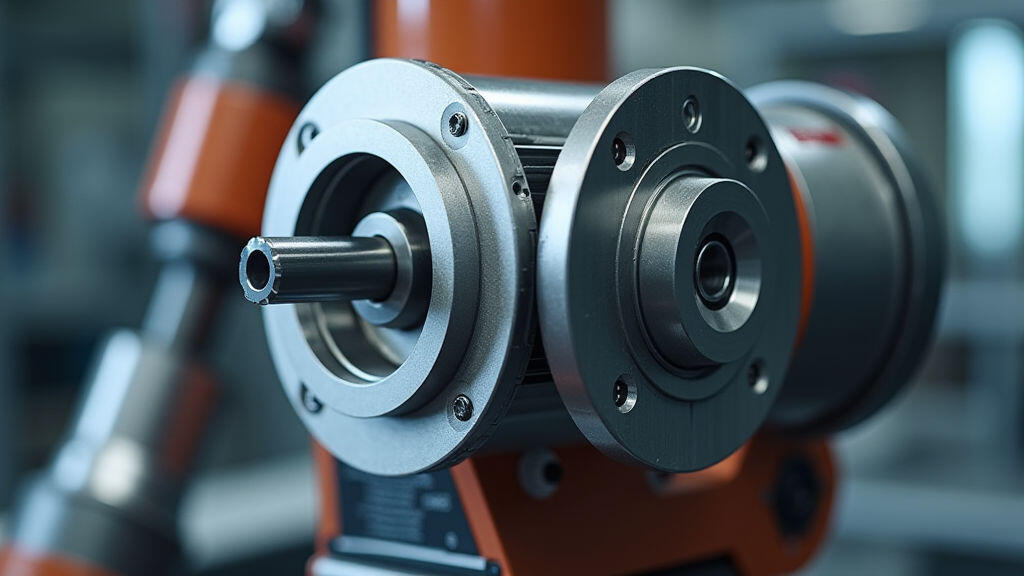

Behind the polished robots and sleek user interfaces lies a quartet of components requiring precision and reliability: sensors, controllers, actuators, and the gear motor reducer. It is the reducer that takes a robust, high‑speed motor and transforms it into a controllable, torque‑rich device suitable for grabbing, rotating, or pushing heavy payloads. When a robot arm raises a ten‑kilogram pallet, the gear motor reducer ensures that the motor’s high revolutions translate into the low‑speed, high‑torque motion the arm requires—ensuring smooth, repeatable movements that are crucial for safety and quality.

The core innovation of the gear motor reducer is its two‑stage power conversion: high rotational speed is first reduced, then combined with a job‑specific gear ratio. The result is a lightweight, compact motor unit that delivers high torque bursts while maintaining low rotational speed. In practical terms, the reducer allows Amazon’s autonomous pods to perform tasks normally reserved for human workers—like lifting a 10‑kg box to a 1.5‑meter shelf—in less than a second and with consistent precision.

Designers employ Coupling Types I and II Dynamics: the first for smooth, linear lifts and the second for quick, angular positioning. This modular approach means that the same motor base can be paired with different reducer ratios to match varied workloads—running a pallet at 70 deg‑s⁻¹ for speedy transit or stopping the arm at 0.5 deg‑s⁻¹ for fine‑grained placement.

Where the gear motor reducer provides true novelty is its compliance with the industrial safety tier UPE 2/3 and IEC 61360 standard, meaning it can safely handle sudden load spikes without catastrophic failure—a vital feature for goods that change weight or balance during transit. Together with precise torque measurement (with a 0.1 % accuracy rating), it furnishes a safety net that keeps robots operating within defined parameters, preventing damage to both goods and equipment.

Market analysts forecast that the global industrial gear motor reducer segment will outpace other motor components by 8 % CAGR from 2024–2030, propelled principally by the adoption of robotic automation in e‑commerce fulfillment, automotive production, and pharmaceuticals. The headlining type—HD gear motors with built‑in reducers—accounts for 62 % of current shipments, with the amplitude of application ranging from conveyor drives to robotic grippers.

Amazon’s release of Panda Swan spurred a domino effect: with the company requiring at least 10 million kg of customized gear motor reducers for its global network, competitors scrambled to meet the demand. This uptick positively impacted manufacturers who had been in the pre‑development stage for low‑speed, high‑torque motors, offering new revenue streams and urging continuous research into materials like titanium alloy and carbon‑fibre composites to minimize weight while boosting strength.

While the gear motor reducer’s mechanical essence remains, the modern iteration is increasingly smart. Built‑in microcontrollers signal motor temperature, vibration, and load directly to an AI‑based predictive maintenance system. This data helps facilities schedule micro‑interventions before failure occurs—a crucial factor for Amazon’s commitment to zero downtime in the 16-hour “24/7/365” fulfillment paradigm.

The trend is a deeper integration of human‑machine interfaces: a single “Smart Motion Suite” empowers multiple robots to share load information and coordinate assignments. Gear motor reducers are the backbone of this ecosystem, shielding high‑speed motors from shocks and allowing real‑time adjustment of gear ratios based on load variations.

Moreover, research is underway to combine super‑elastic polymer bearings with the traditional steel gear box to further reduce friction losses. Early prototypes show up to 1.5 % increase in efficiency—meaning lower energy consumption per operation—a vital stat for companies moving toward carbon‑neutral operations.

The update to Amazon’s robotics isn’t simply a win for a single corporate giant. It reflects an acceleration in automation standards that other industries—like automotive assembly, aerospace spare parts, and even medical diagnostics—will follow. The gear motor reducer, the silent enabler of these advances, is evolving into a critical component. For small‑to‑medium manufacturers, small changes in gear ratios or material composition can dramatically improve productivity, reduce operational costs, and extend machine lifespans.

By demanding consistent torque demands in high‑speed, low‑speed, and high‑load scenarios, the gear motor reducer frames the conversation for future automation innovations. Whether we talk about warehouses, autonomous underwater vehicles, or renewable energy turbines, it is the micro‑mechanism that translates electronic control signals into real-world movements. The global supply chain’s next chapter will thus read less about the robots themselves and more about the gears that give them precision.

Amazon’s public debut of the Panda Swan robot arm has injected a new chapter into the automation story—one that speaks loudly to market analysts, manufacturers, and consumers alike. Though the robots and cameras capture immediate attention, the gear motor reducer is the unsung hero ensuring those robots move smoothly and reliably. Its blend of high torque, minimal speed, and reliable safety makes it indispensable for any system that relies on precision under varying loads.

As the global push for automation deepens, the demand for gear motor reducers will rise, ushering in opportunities for material innovation, smarter integration, and more reliable factory floor operations. The lesson? Sometimes the most transformative trends revolve around the smallest yet the most critical parts—like the gear motor reducer that quietly propels the next wave of intelligent manufacturing.

Leave A Reply

Your email address will not be published. Required fiels are marked